Amsol Capabilities

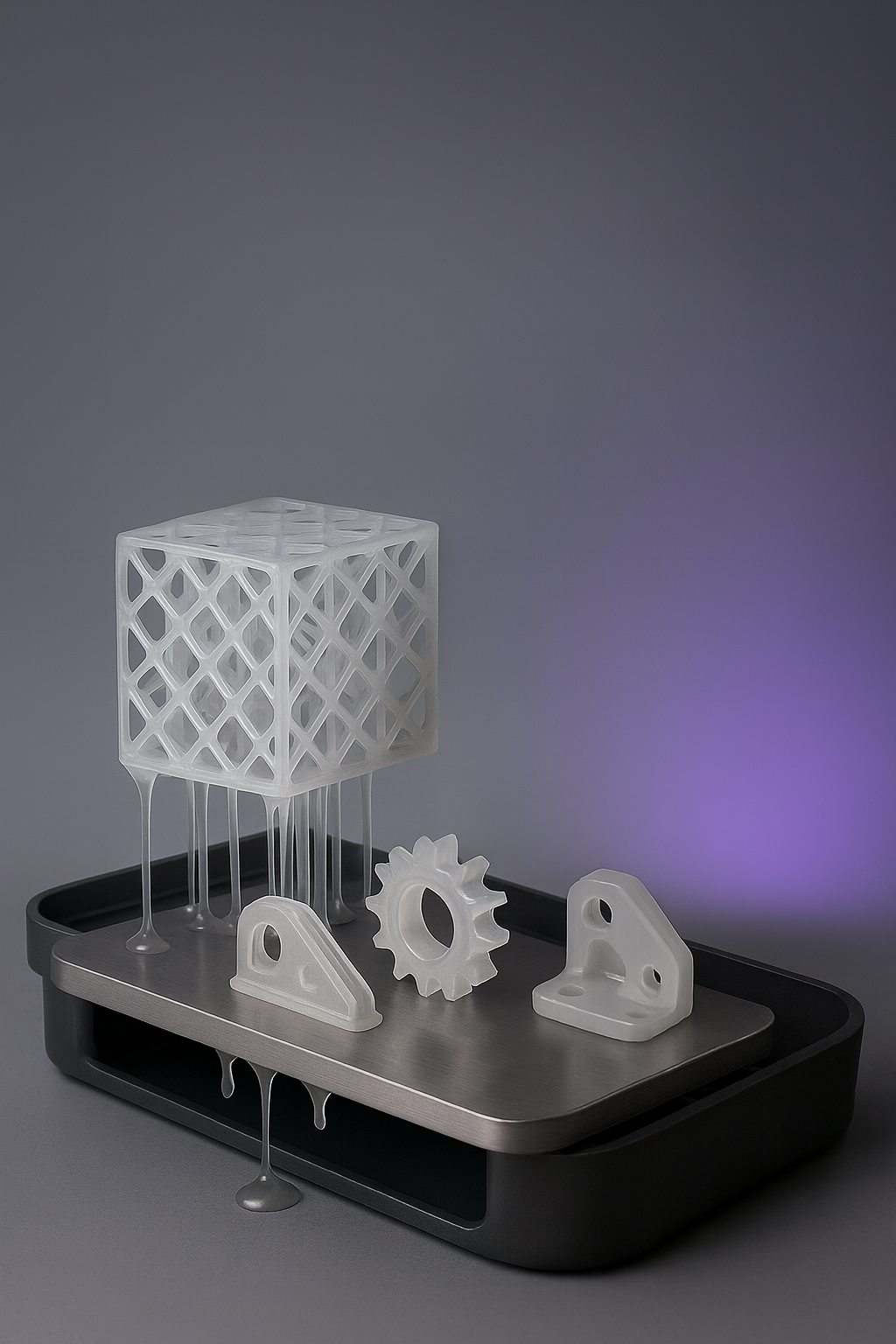

3D Printing, Built for Momentum

From fast prototypes to bridge production, we print strong, accurate parts across plastics and metals, add machining and finishing, and ship fit-checked, labeled assemblies. One accountable partner from CAD to carton with clear lead times and dependable quality documentation.

- ISO 9001:2015

- 40+ Years Expertise

- ASTM / DIN / EN / JIS

- 30+ Countries

Go from idea to installed part

Design help, wide processes, post-processing, and reliable, documented deliveries.

- DFM adjusts wall, ribs, orientation for strength

- Multiple print techs matched to geometry and volumes

- Dimensional checks; machining for critical interfaces

- Surface finishing tuned to function or appearance

- Assemblies kitted, labeled, ready for line use

- Clear schedules; batch-coded, traceable shipments

Prototypes that scale into supply

We prove parts quickly, then stabilize specs for repeatable runs.

- Rapid iterations validate fit, function, ergonomics

- Process windows locked for strength and cosmetics

- Inserts, threads, tapping added post-print as needed

- Jigs, gauges, and CMM verify critical features

- Pack-out protects surfaces and dimensional stability

Amsol 3D Printing Capabilities

From CAD to ready parts

Lead Time

Same-week prototypes; scheduled bridge runs for continuity

Processes

FDM, SLA, SLS, MJF, DMLS; selection by need

Tolerances

Printer-class limits; critical faces post-machined to spec

Prototyping

Fast loops; design tune-ups; material swaps validated

Quality

Inspection reports, material certs, and traceable batches

Explore processes, materials and finishes we deploy for printed parts.

FDM (Filament)

Durable prototypes and fixtures, large parts, cost-effective runs.

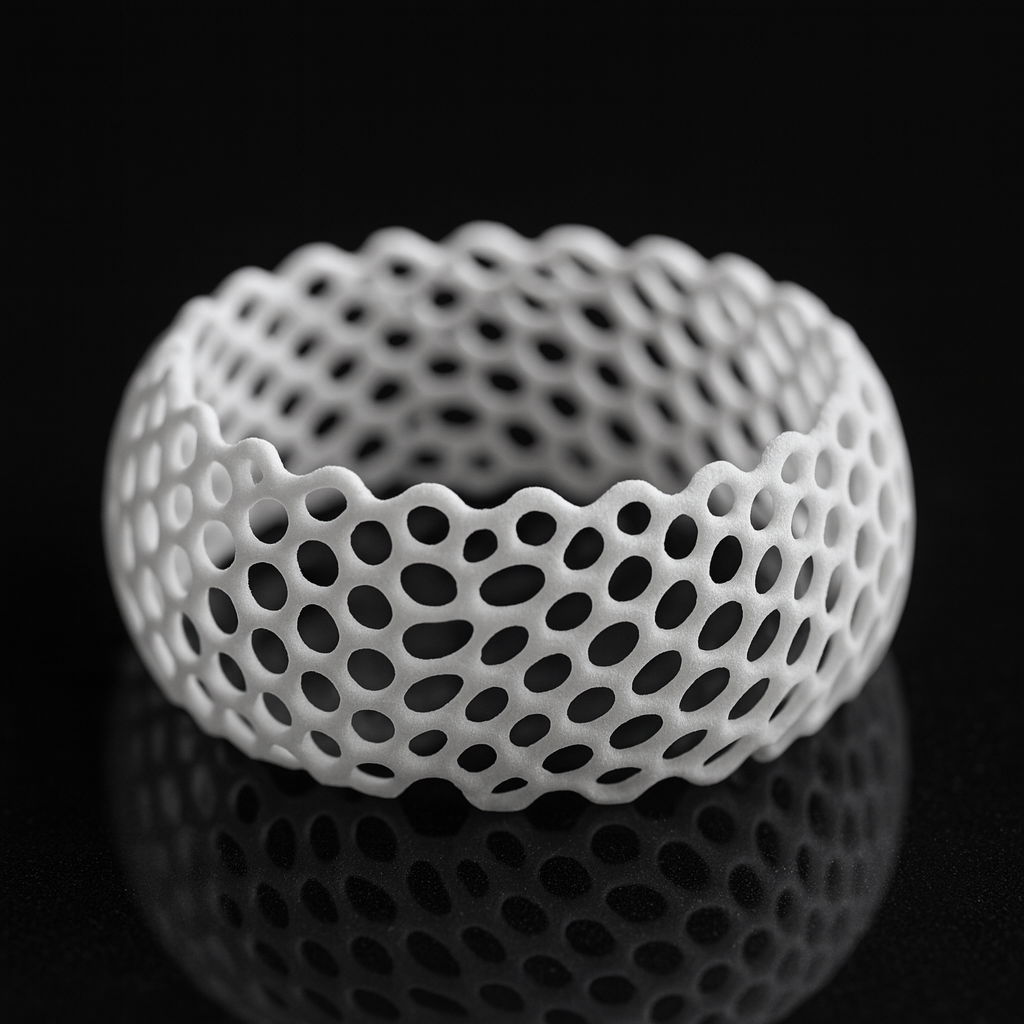

SLA (Resin)

High detail and smooth surfaces, clear and cosmetic options.

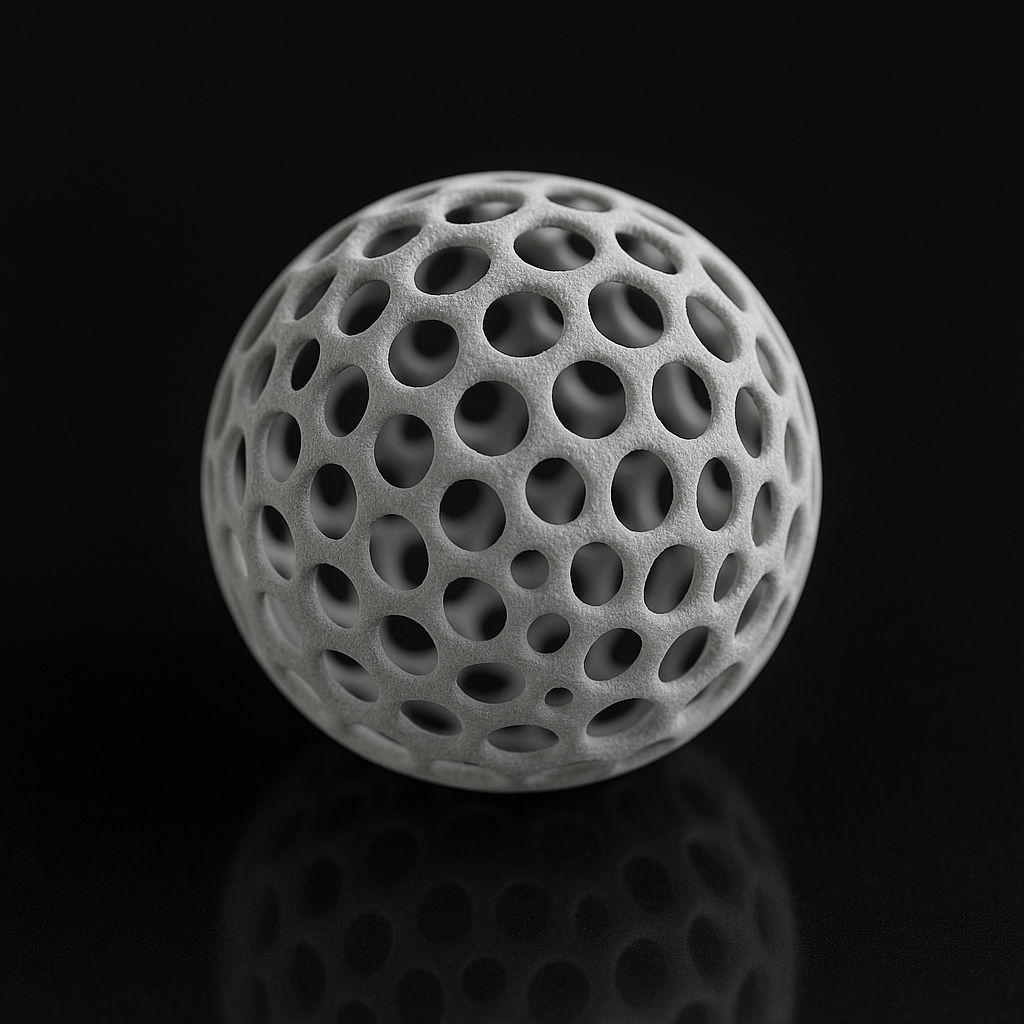

SLS (Nylon Powder)

Strong, isotropic parts without supports, great for snaps and hinges.

MJF (Nylon)

Fast, consistent batches, good detail with dye options.

PLA (proto)

ABS / ASA

PC

Nylon PA12 / PA11

Nylon Glass-Filled

TPU / TPE

PETG

PEEK (selective)

SLA Standard / Tough / Clear / High-Temp

AlSi10Mg

Stainless Steel 17-4PH / 316L

Ti-6Al-4V (as sourced)

Bead / Media Blasting

Vapor Smoothing (select plastics)

Dyeing (Nylon / MJF)

Painting / Priming

Tapping / Thread Inserts

CNC Post-Machining

Heat Treatment (metals)

Brushing / Polishing

Laser Marking

Get the Brochure – Everything You Need in One Place.

Discover expert tips on design, materials, geometry, and tolerances—download the brochure now.