Amsol Solution

Product Optimization, Proven In Production

We refine cost, yield, and reliability using real build data—targeted changes that protect performance while lowering total landed cost.

- ISO 9001:2015

- 40+ Years Expertise

- ASTM / DIN / EN / JIS

- 30+ Countries

Product Improvement Approach

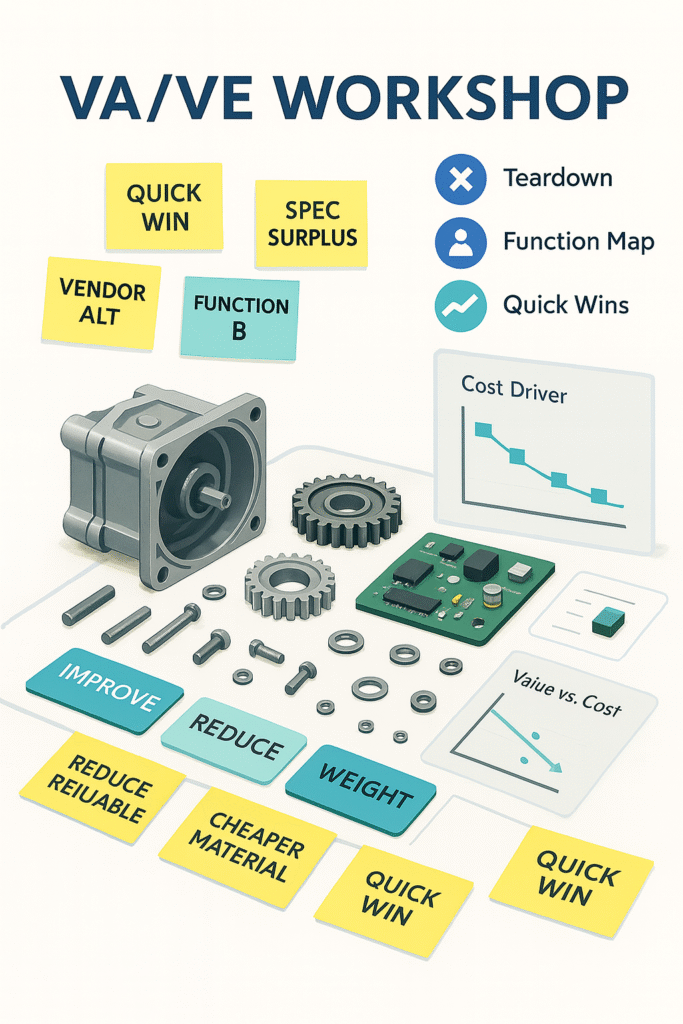

- VA/VE sprints

- Material/finish upgrades

- Tolerance & cycle tuning

- Part/assembly consolidation

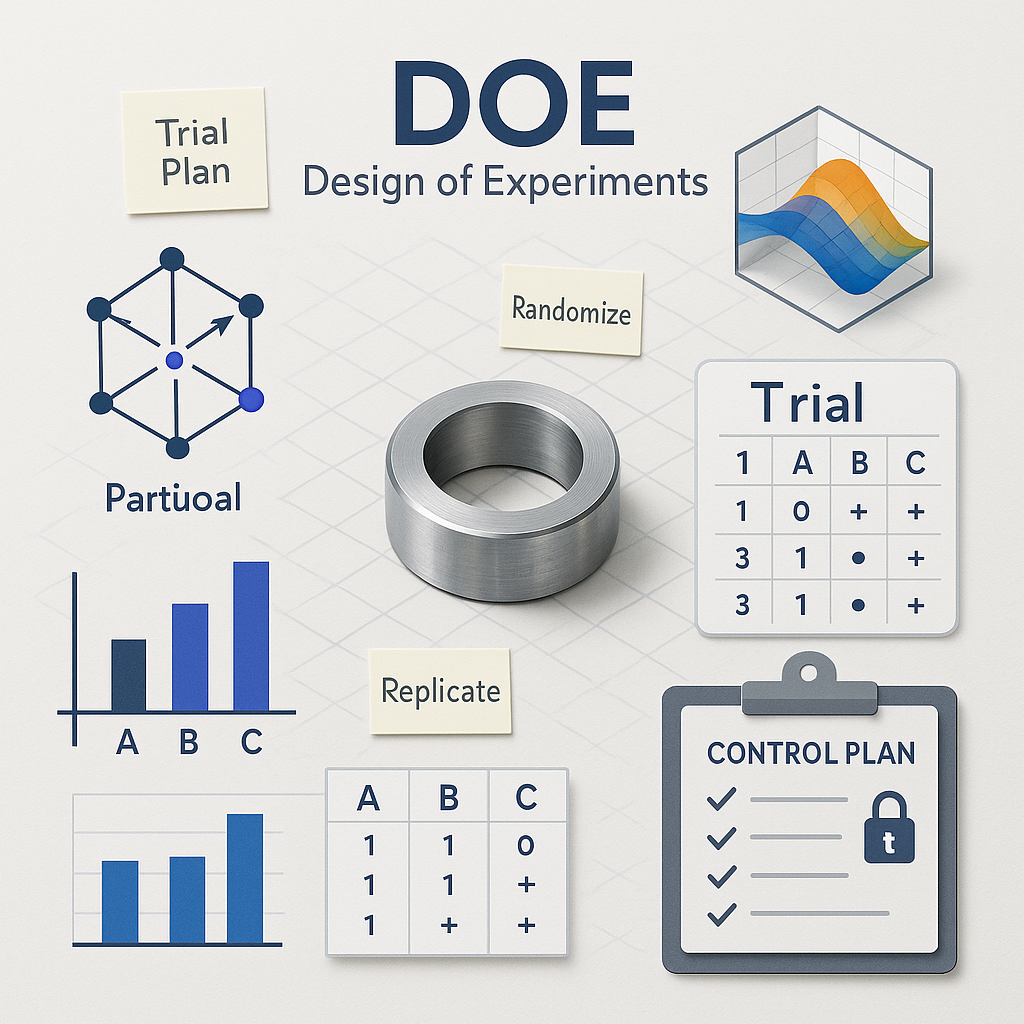

Robust, data-driven, low-risk changes

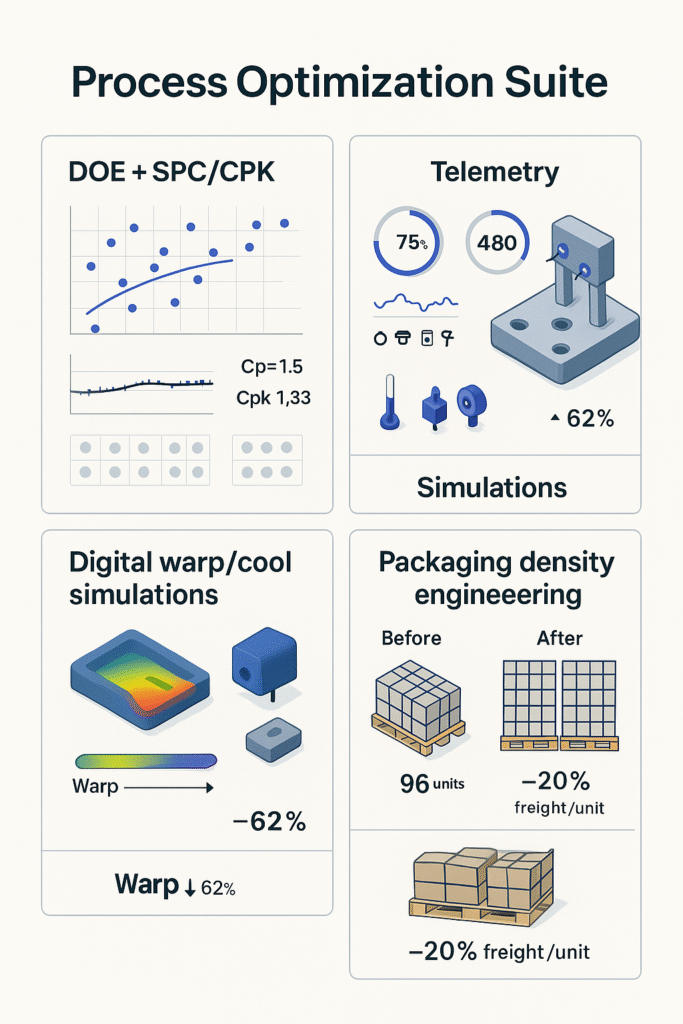

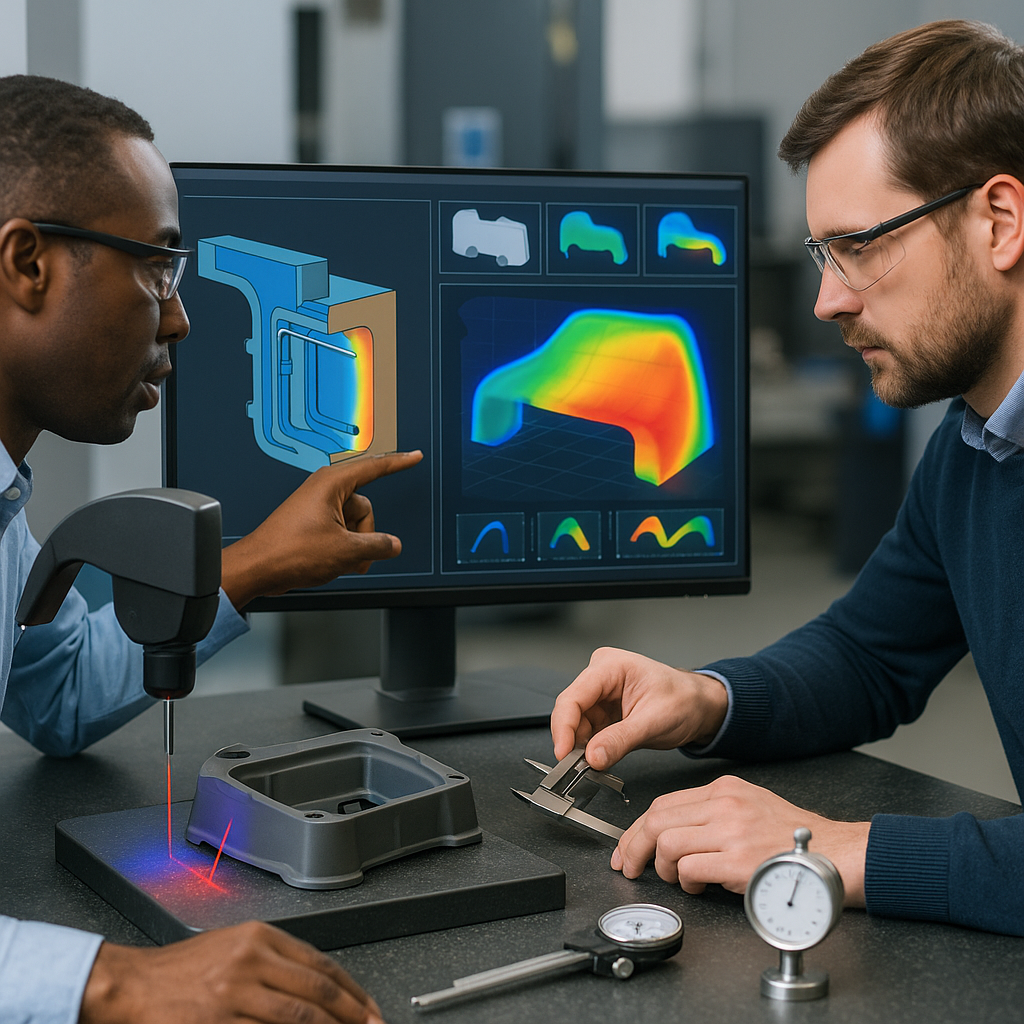

- DOE with SPC/CPK

- Tooling and fixture telemetry

- Digital warp/cool simulations

- Packaging density engineering

Advanced optimization, measurable outcomes

Ensuring every part meets specification through disciplined, data-driven quality control.

VA/VE Workshops

Cross-functional teardown, function mapping, and cost drivers prioritized for quick wins.

Design of Experiments (DOE)

Structured trials converge optimal parameters; results locked in control plans.

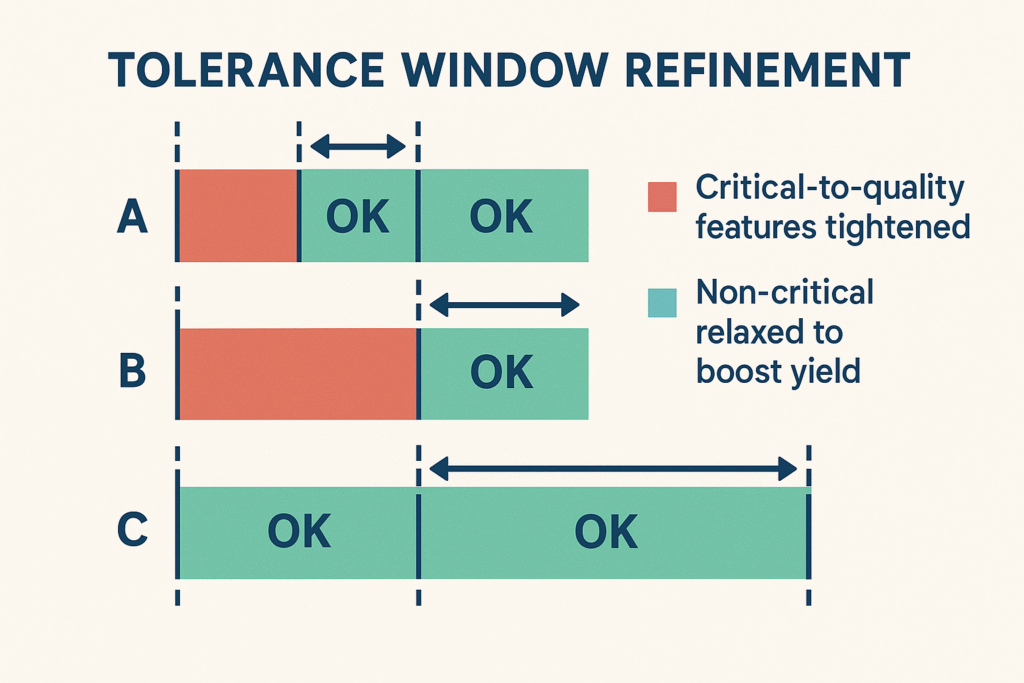

Tolerance Window Refinement

Critical-to-quality features tightened where needed; non-critical relaxed to boost yield.

Optimization toolset and enablers

SPC/CPK dashboards

Process parameter studies

Mold/fixture sensors

Cycle-time de-bottlenecking

Scrap/defect Pareto analysis

Material equivalency mapping

Coating life improvements

Assembly step reduction

Line balance adjustments

Don’t Just Take Our Word for It

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s

Lorem Ipsum Lorem

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s

Lorem Ipsum Lorem

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s

Lorem Ipsum Lorem