Amsol Capabilities

Trusted Aerospace Manufacturing Partner

- ISO 9001:2015

- 40+ Years Expertise

- ASTM / DIN / EN / JIS

- 30+ Countries

From Prototype to Production, Seamlessly

Prototyping

Rapid builds prove geometry, materials, and manufacturability, enabling fast design iteration, cost visibility, and supplier alignment for downstream scale-up.

Fast feedback

3D printing & CNC & allow parts in days, not weeks.

Cost de-risking

Early visibility into tooling and machining budgets.

Supplier alignment

Digital models matched to in-house processes for scale readiness.

Engineering Validation Testing

Functional prototypes validate core performance and safety margins, informing tolerances, process windows, and initial PFMEA direction for production readiness.

Performance proof

Validated with ±0.02 mm & machining accuracy.

Safety margins

Tested against ASTM/DIN/EN compliance standards.

Process direction

PPAP & FMEA frameworks guide production stability.

Design Validation Testing

Validate part strength, functionality, and finish with production-grade injection molding at prototype speeds and CNC machining with broad finishing options.

Strength & Vibration Testing

Rapid Design Molds with steel tooling at low quantities

Appearance & Durability

Wide post-processing options for CNC Machined parts

Design Validation Testing

Pre-production parts confirm design across environments and variability, locking specifications, interfaces, and assemblies prior to tooling freeze.

Environmental proofing

Salt spray & heat treatment tests ensure durability.

Interface fit

Multi-axis machining guarantees precise assembly compatibility.

Spec lock

CMM and spectro analysis certify dimensional consistency.

Production Validation Testing

Pilot lots exercise tools, cycles, and inspection plans, stabilizing yields and training operators ahead of controlled ramp.

Tooling stability

Forging & die-casting validated under production cycles.

Yield confirmation

98% first-pass yield benchmarked across industries.

Operator training

Documented SOPs ensure consistent shop-floor execution.

Explore processes, materials and finishes trusted for aerospace.

Investment Casting

Near-net shapes enabling complex geometries efficiently.

Precision Forging

Ideal for load-bearing structural components requiring reliability.

CNC Machining

Tight tolerances and repeatable quality throughout.

EDM Machining

Precision features in hard-to-machine alloys accurately.

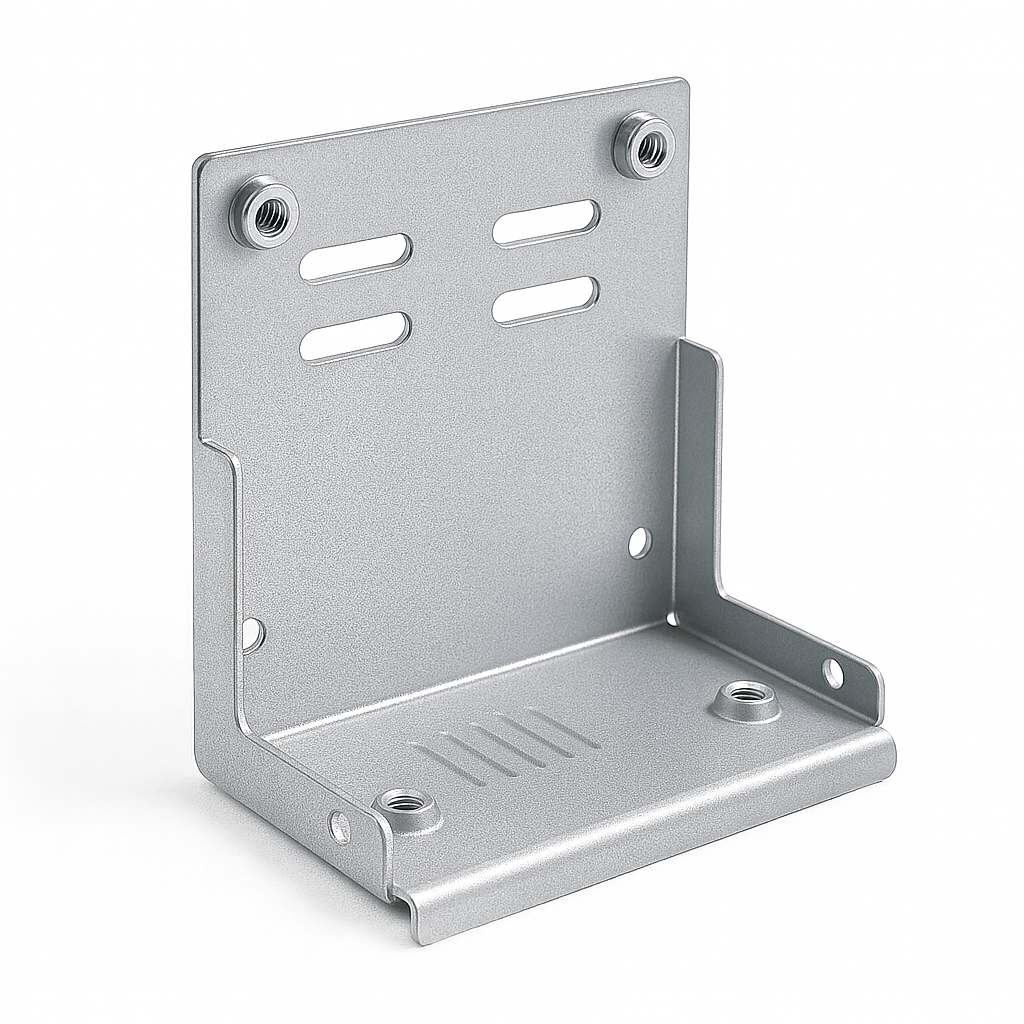

Sheet Fabrication

Laser cutting, punching, bending for enclosures.

Surface Treatment

Anodizing, coatings, blasting for protection longevity.

Carbon Steel

Shot Blasting

Why Choose AMSOL

Process Depth

Casting, forging, machining, and additives under one roof. One team owns outcomes. Faster validation, fewer vendors, tighter control.

Certified Quality

ISO-driven systems with documented PPAP-style controls, CMM and spectro checks, and batch-coded traceability. Reliability isn’t claimed—it’s recorded.

Global Supply

Presence in multiple countries with export-ready packaging and JIT delivery lanes. Programs scale smoothly from pilot to steady production.

CASE STUDY

AMSOL Manufacturing Ecosystem – Driving Industrial GrowthThrough Collaboration

Simplified Sourcing for Aerospace Programs

- Brackets

- Housings

- Manifolds

- Gears

- Shafts

- Flanges

- Fittings

- Enclosures

- Heat sinks

- Mounts

- Bushings

- Pins