Amsol Capabilities

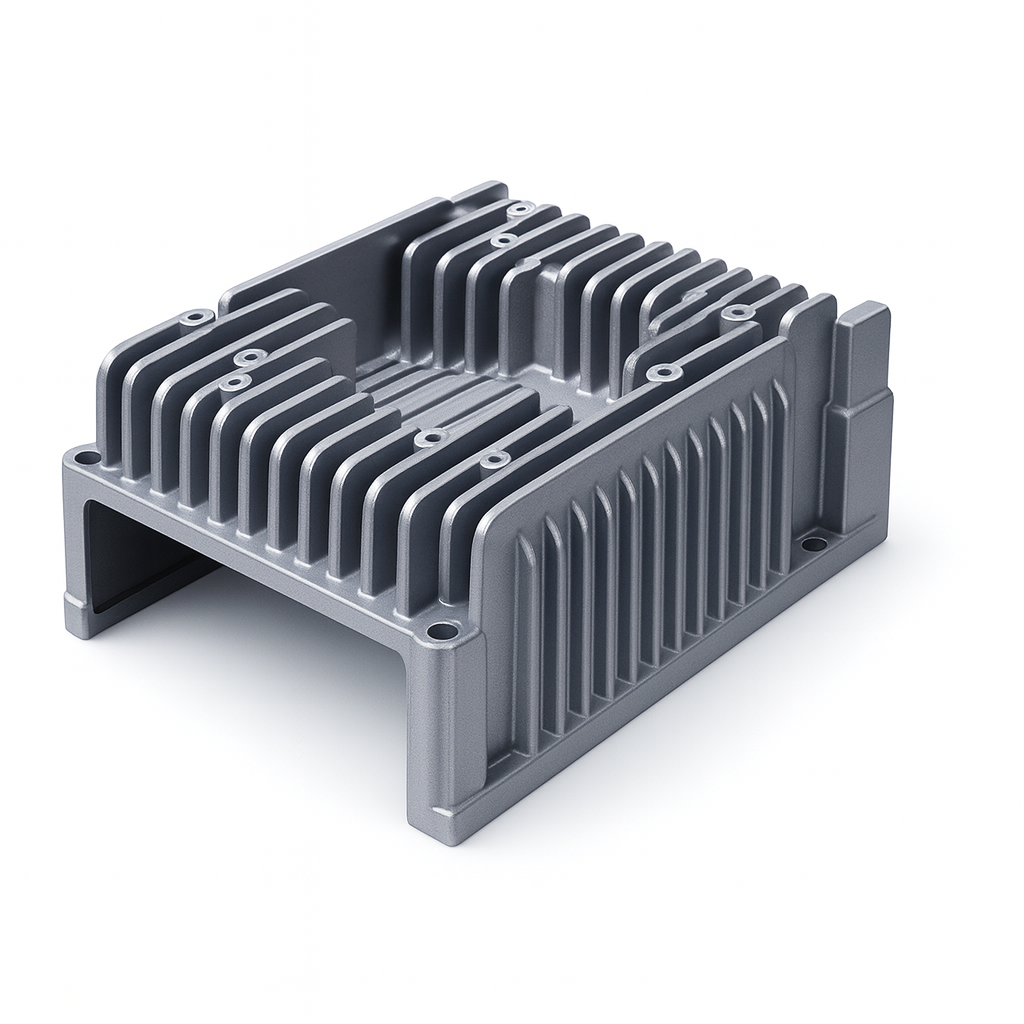

Aluminium Die Casting, Built for Scale

From DFM and gating/cooling simulation to robust tooling and PPAP, we cast aluminium parts for strength, weight, and cost—then machine, finish, inspect, and ship line-ready. One accountable partner from prototype to production with documented quality and traceable lots.

- ISO 9001:2015

- 40+ Years Expertise

- ASTM / DIN / EN / JIS

- 30+ Countries

Lightweight parts without guesswork

Engineering-first casting with integrated machining, finishing, inspection, and logistics.

- DFM trims weight while protecting stiffness and features

- Tooling designed for life, serviceability, and stable yields

- Controlled fill reduces porosity; consistent cosmetics at scale

- Critical faces post-machined to assembly-ready tolerances

- PPAP, SPC, CMM reports ensure specification conformance

- Batch coding and JIT dispatch aligned to your schedules

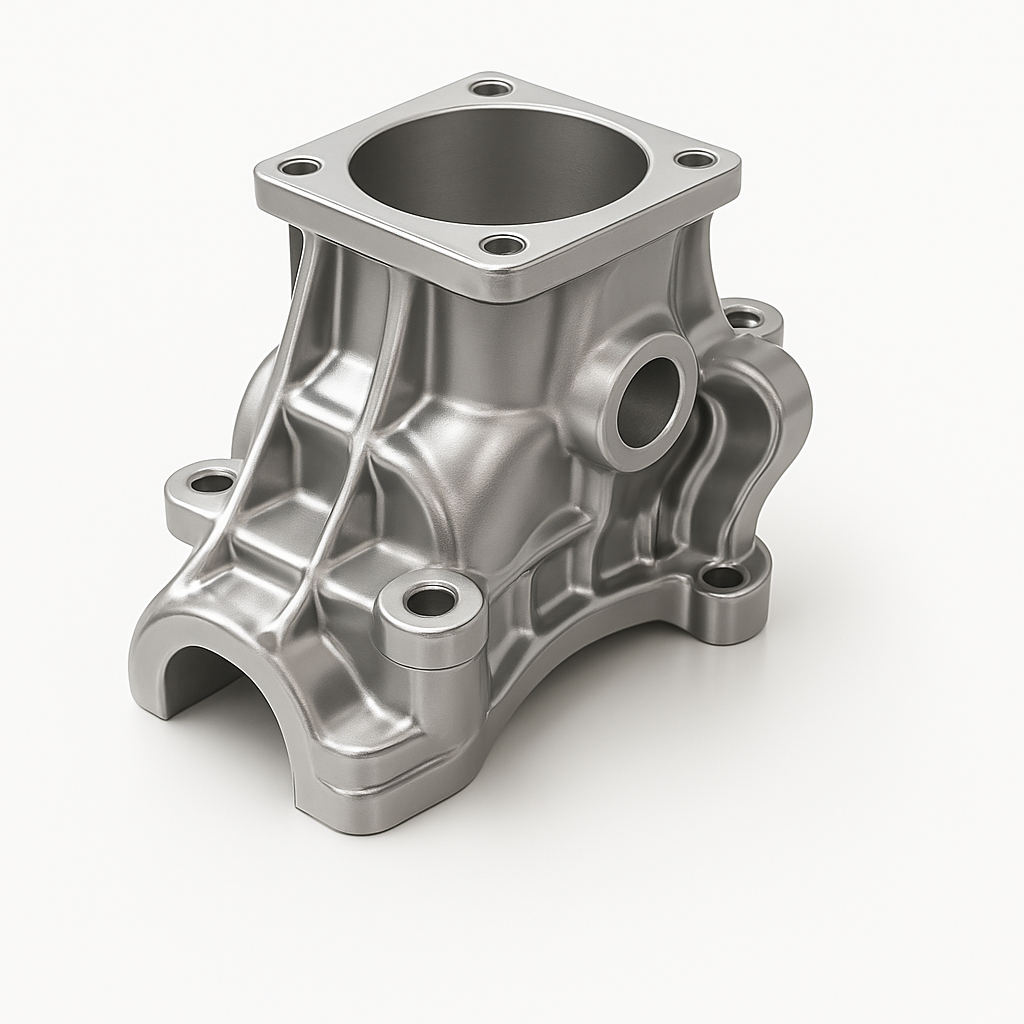

Strength, accuracy, and repeatability

We stabilize process windows early and safeguard them through ramp.

- Samples validate gating, runners, vents, and cooling strategy

- Preventive tool care avoids flash, porosity, and dimensional drift

- Vacuum or squeeze options improve density for load zones

- Inline checks confirm critical datums and wall uniformity

- Pack-out engineered for surface and corner protection

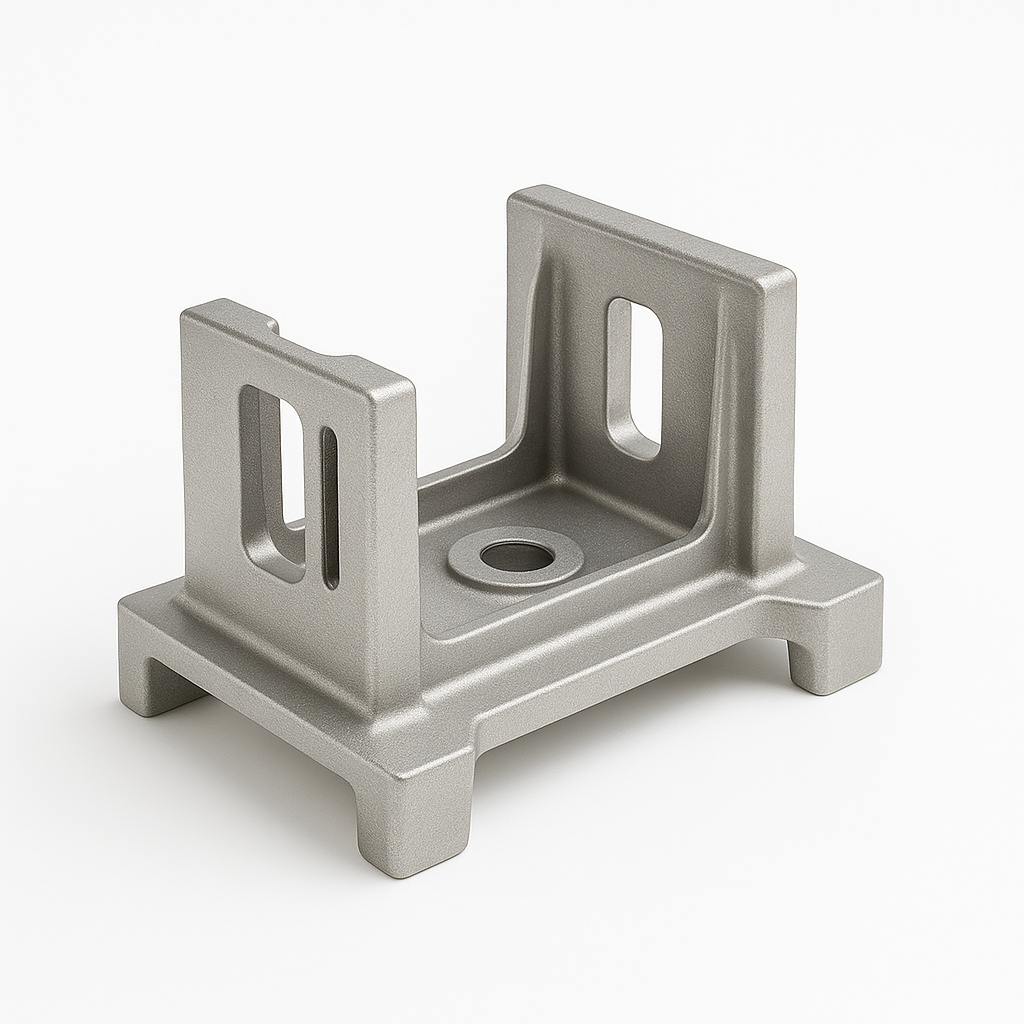

Amsol Aluminium Die Casting Capabilities

From toolroom to truck-ready parts

Lead Time

Rapid T1s; controlled ramps; dependable serial cadences

Tooling

Gating/cooling simulation, quick-change inserts, maintenance logs

Tolerances

Stable tight features; CMM verification and SPC capability

Prototyping

Bridge tools, insert swaps; early PPAP planning and trials

Quality

PPAP, FMEA, CPK; spectro checks, leak tests, full traceability

Explore processes, alloys, and finishes we use for aluminium castings.

High-Pressure Die Casting

Fast cycles, complex geometry, cost-efficient volumes with consistency.

Low-Pressure Die Casting

Controlled fill, lower porosity, better mechanicals on thicker sections.

Gravity Die Casting

Reliable medium-run option, stable walls and dimensional control.

Vacuum-Assisted Casting

Reduced gas entrapment, improved density, cleaner surfaces for finishing.

Squeeze Casting

Higher integrity, heat-treatable parts, strong load-bearing regions.

Integrated CNC Machining

Datum-driven workholding, multi-axis ops, assembly-ready critical faces.

AlSi9Cu3 (A380 / ADC12)

AlSi10Mg (A360 / EN AC-43000)

AlSi7Mg (A356)

AlSi12

AlMg alloys (select)

Shot / Bead Blasting

Vibratory Tumbling

Impregnation (Porosity Sealing)

Chromate Conversion (Alodine)

Powder Coating

Anodizing (select alloys/processes)

Machining & Deburring

Heat Treatment (GDC/LPDC-suitable alloys)

Laser Marking

Get the Brochure – Everything You Need in One Place.

Discover expert tips on design, materials, geometry, and tolerances—download the brochure now.