Amsol Capabilities

CNC Machining, Built for Precision

- ISO 9001:2015

- 40+ Years Expertise

- ASTM / DIN / EN / JIS

- 30+ Countries

One supplier from print to pallet

- DFM to reduce setups, cycle time, cost

- Stable jigs, datums, and process windows

- Multi-axis efficiency for complex geometries

- CMM-backed inspection with SPC records

- Assembly-ready parts with clean deburring

- Batch coding and on-time dispatch

98% First-Pass Yield

98% First-Pass Yield

When 98% of products pass inspection the first time, efficiency isn’t a goal—it’s the standard.

CNC Machining at Amsol

Repeatability you can bank on

- CAM strategies tuned for tool life, finish

- Tool libraries standardized for consistency

- In-cycle probing verifies critical datums

- Preventive maintenance keeps tolerances tight

- Pack-out engineered for line-side flow

CNC Machining at Amsol

From Model to Measured Parts

Lead Time

Rapid prototypes; controlled ramps; reliable serial cadence

Tooling/fixturing

Rigid datums, quick-change, mistake-proofed setups

Tolerances

GD&T control, CMM verification, documented capability (CPK)

Prototyping

Fast iterations; bridge runs; inspection plans matured early

Quality

PPAP, FMEA, MSA; traceable lots and digital reports

Explore our processes, materials and finishes for production-ready machined parts.

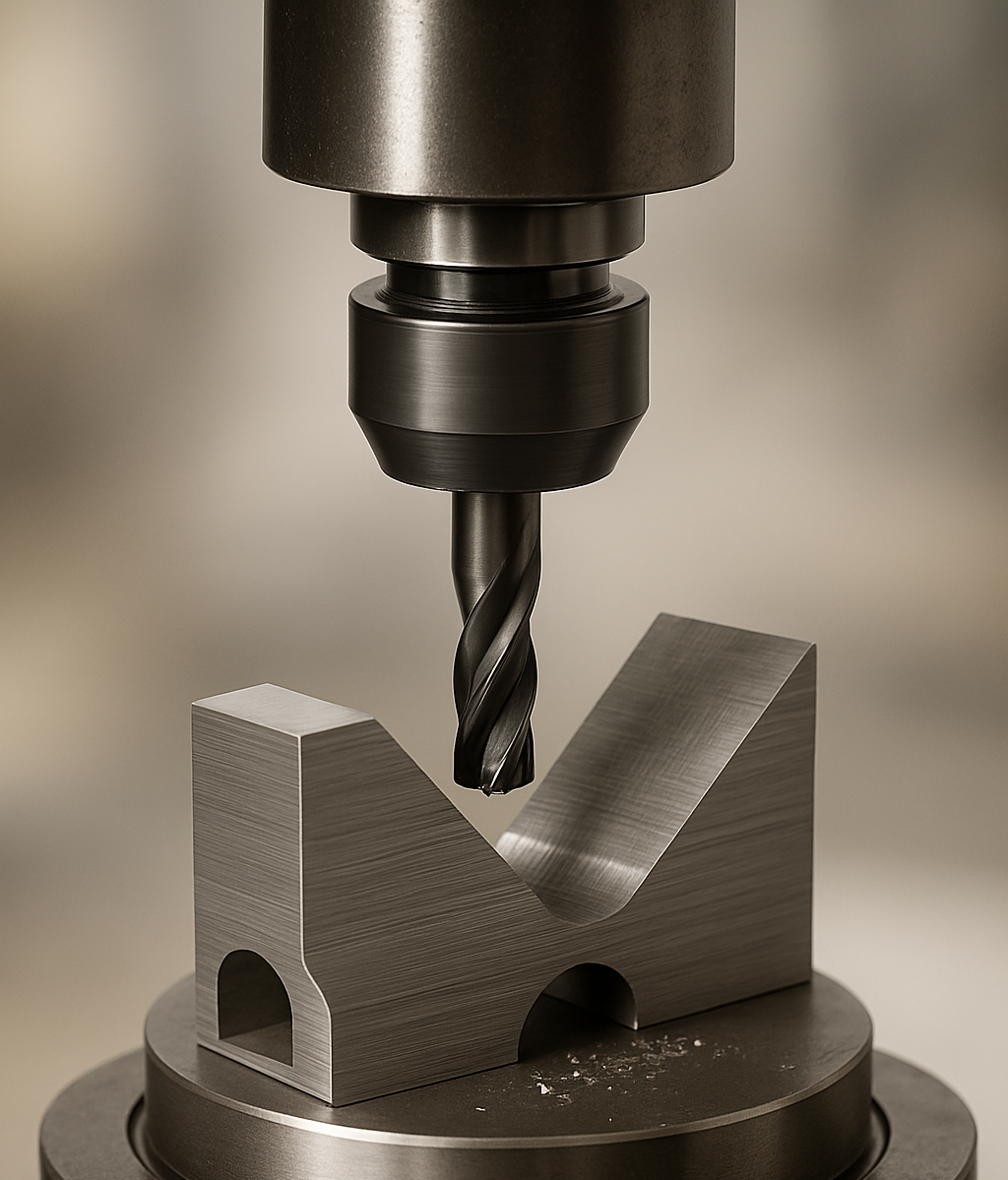

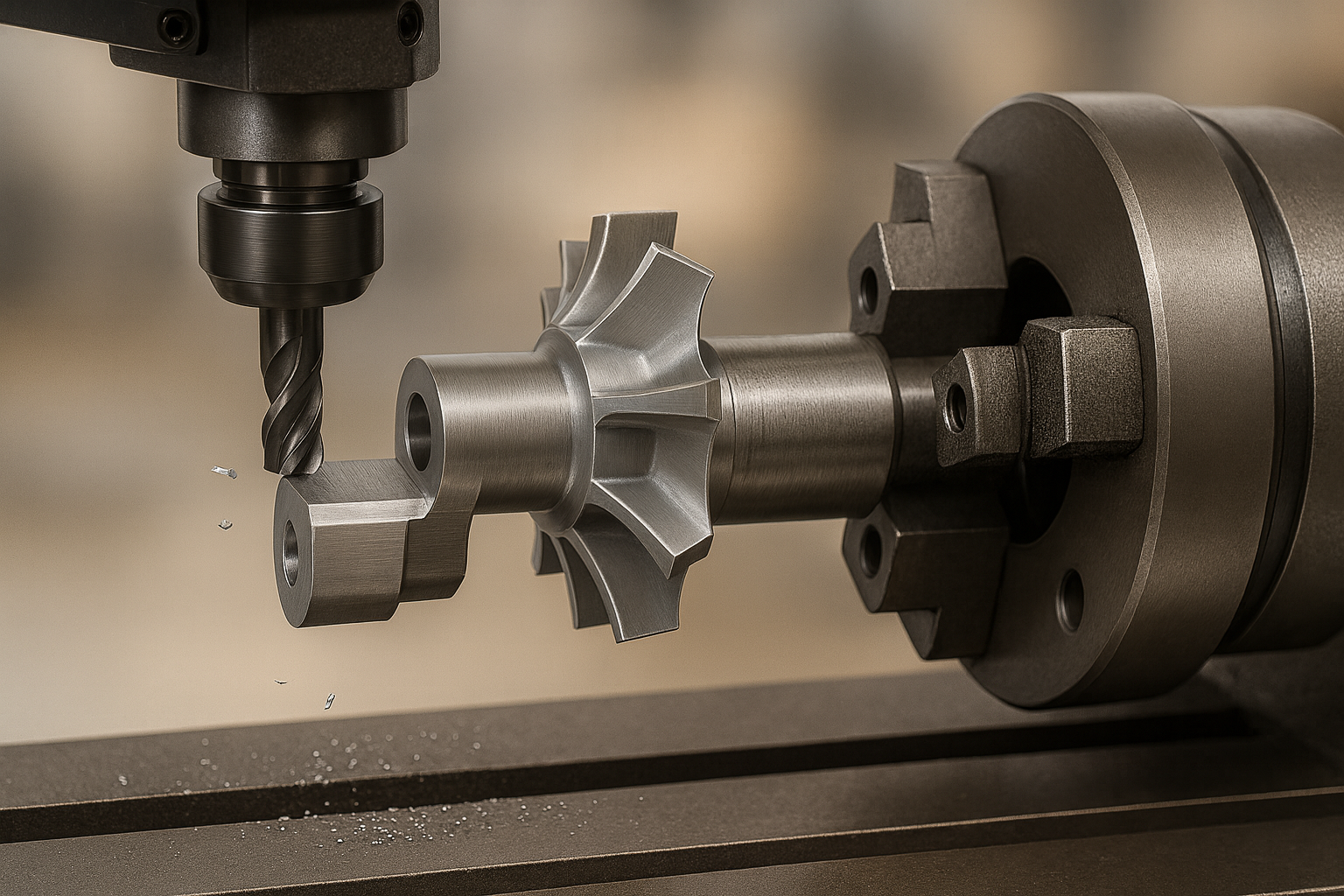

CNC Milling

Efficient prismatic machining, tight flats and pocket accuracy.

Wire EDM

Sharp internal corners, profiles, no burrs on delicate sections.

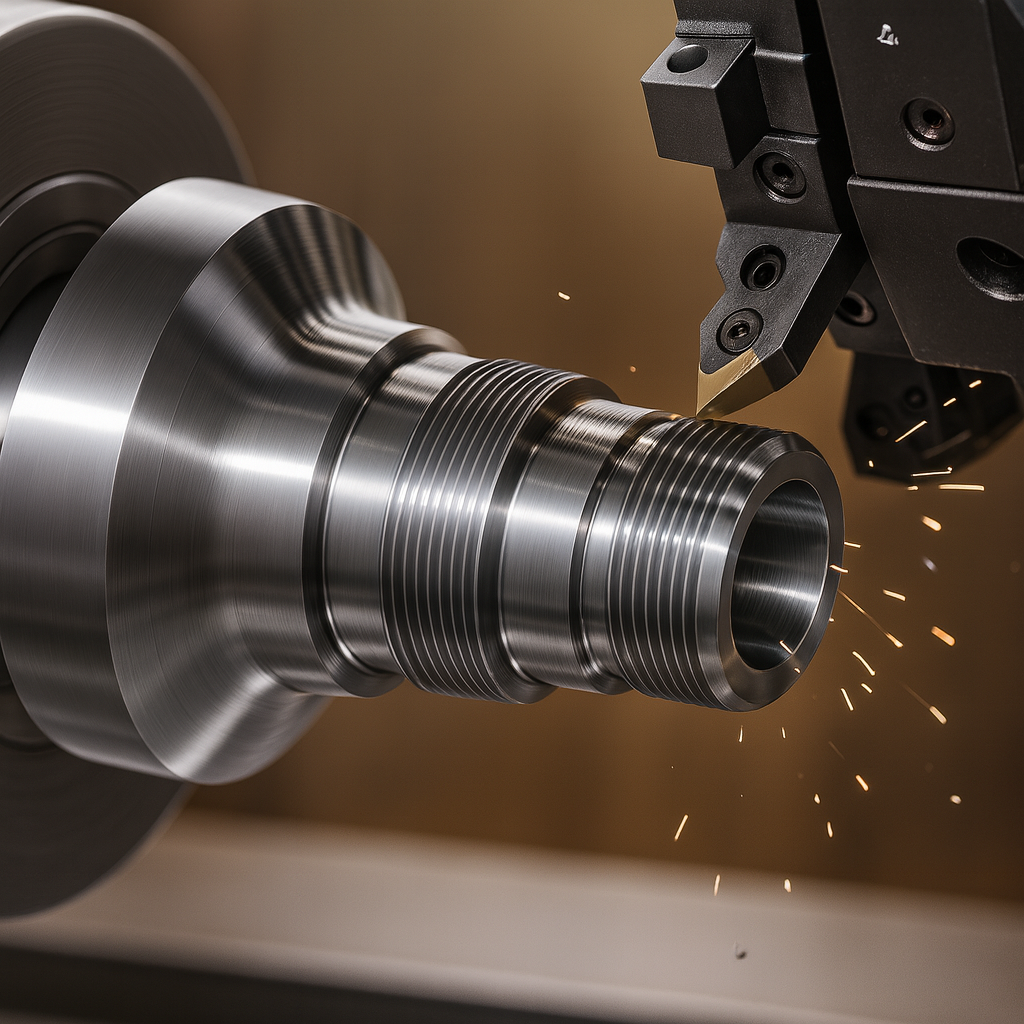

CNC Turning

Concentricity and surface finish, steady control of critical diameters.

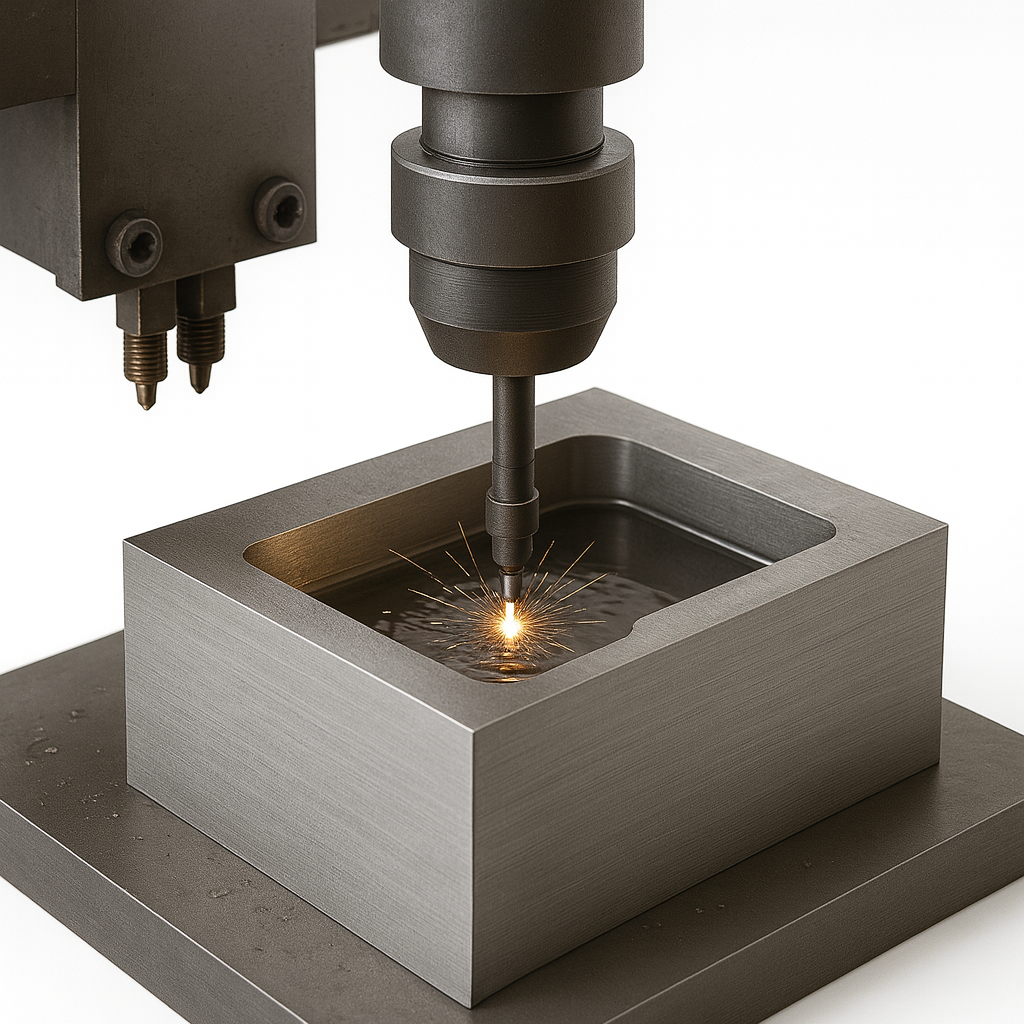

Sinker EDM

Fine cavities and textures, repeatable detail in hard alloys.

Mill-Turn

Milled features on turned parts, cycle-time and handling reduced.

Surface Grinding

Flatness and parallelism control, tight finishes on wear faces.

Bead Blasting

Anodizing

Hard Anodizing

Black Oxide

Chromate Conversion (Alodine)

Powder Coating

Brushing / Polishing

Laser Marking