Amsol Industries

Oil & Gas Manufacturing, Assured

- ISO 9001:2015

- 40+ Years Expertise

- ASTM / DIN / EN / JIS

- 30+ Countries

From Prototype to Field-Ready

Prototyping

Rapid builds validate geometry, materials, and manufacturability for pressure-bearing parts, enabling quick iteration, cost visibility, and supplier alignment.

Fast Feedback Loops

Prototype/additive runs shorten redesign cycles.

Cost de-risking

Early route choice limits tooling rework.

Supplier alignment

Shared drawings/specs and PPAP intent early.

Engineering Validation Testing (EVT)

Functional prototypes verify performance and safety margins under controlled tests, guiding tolerances and process windows for corrosive/pressure service.

Performance validation

Bench tests at rated pressure/flow.

Safety margins

Sections/materials sized for extremes.

Process Direction

PFMEA and capability targets set.

Design Validation Testing

Pre-production units confirm design across environments and variability, validating specs, interfaces, and assemblies before tooling freeze.

Environmental Proofing

Corrosion/temperature and media compatibility checks.

Interface Assurance

Fit checks with valves, pumps, actuators.

Specification Lock

Final BOM, drawings, inspection plans.

Production Validation Testing (PVT)

Pilot lots exercise tooling, cycles, and inspection plans at rate, stabilizing yields and preparing operators for ramp.

Tooling stabilization

Cycle time and wear verified at line speed.

Yield confirmation

SPC with real CMM trend data.

Operator Training

Standard work and checklists finalized.

Production

Serial manufacturing delivers repeatable, traceable components with documented quality and synchronized logistics for dependable field performance.

Stable Quality

ISO 9001:2015 QMS and audits.

Traceable Lots

Batch IDs linked to material certs.

Continuous Improvement

NCR/CAPA loops and delivery reviews.

Processes, materials and finishes AMSOL deploys for oil & gas programs.

Investment Casting

Near-net shapes for complex valve bodies. Reduces machining; stable, repeatable surfaces.

Sand & Shell Casting

Robust housings for heavy service. Flexible gating; durable structures.

Precision Forging

High strength for flanges and fittings. Superior grain flow; low defect rates.

CNC Machining

Multi-axis accuracy for sealing interfaces. Assembly-ready; documented inspections.

EDM Machining

Sharp internal features in hard alloys. Burr-free, complex corners.

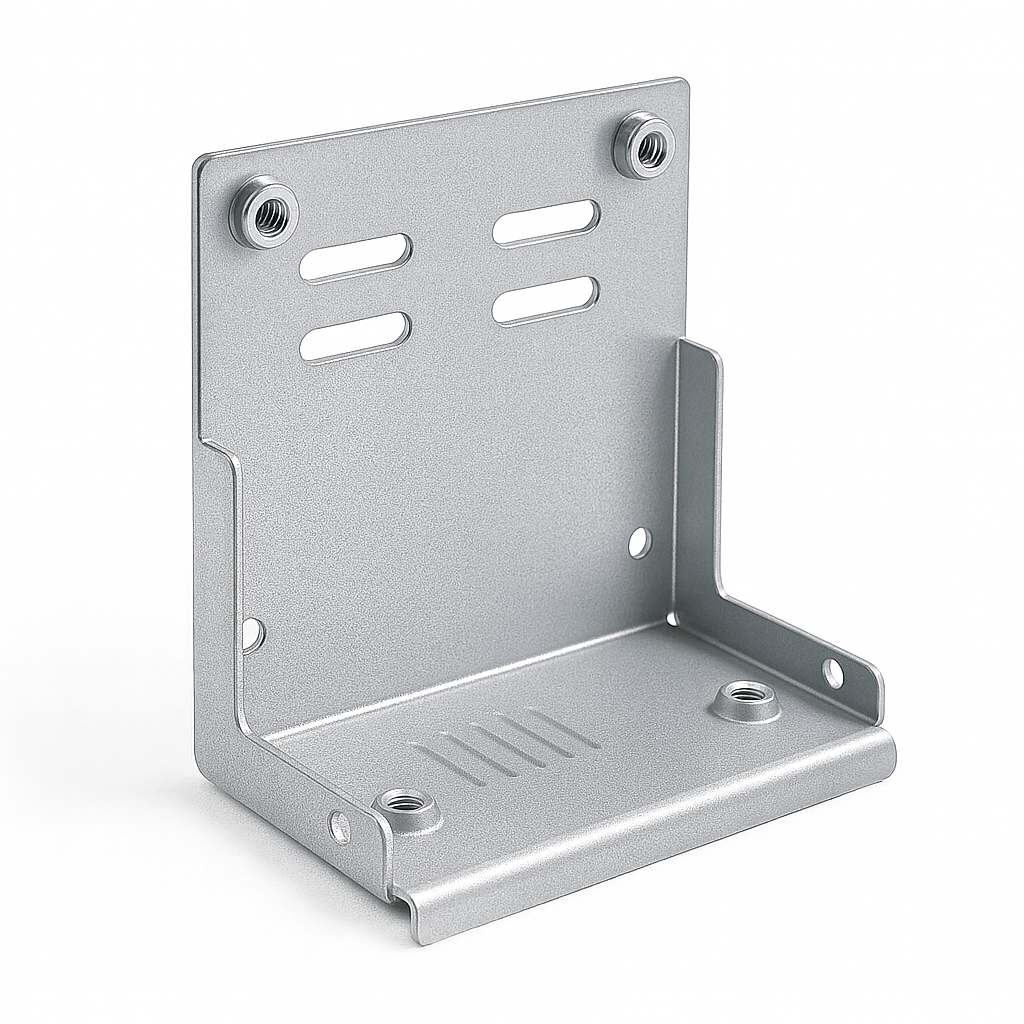

Sheet Metal

Enclosures, guards, mounting panels. Laser, punch, bend; fast throughput.

Powder Metal

Economical precision for bushings/pulleys. High utilization; consistent sizing.

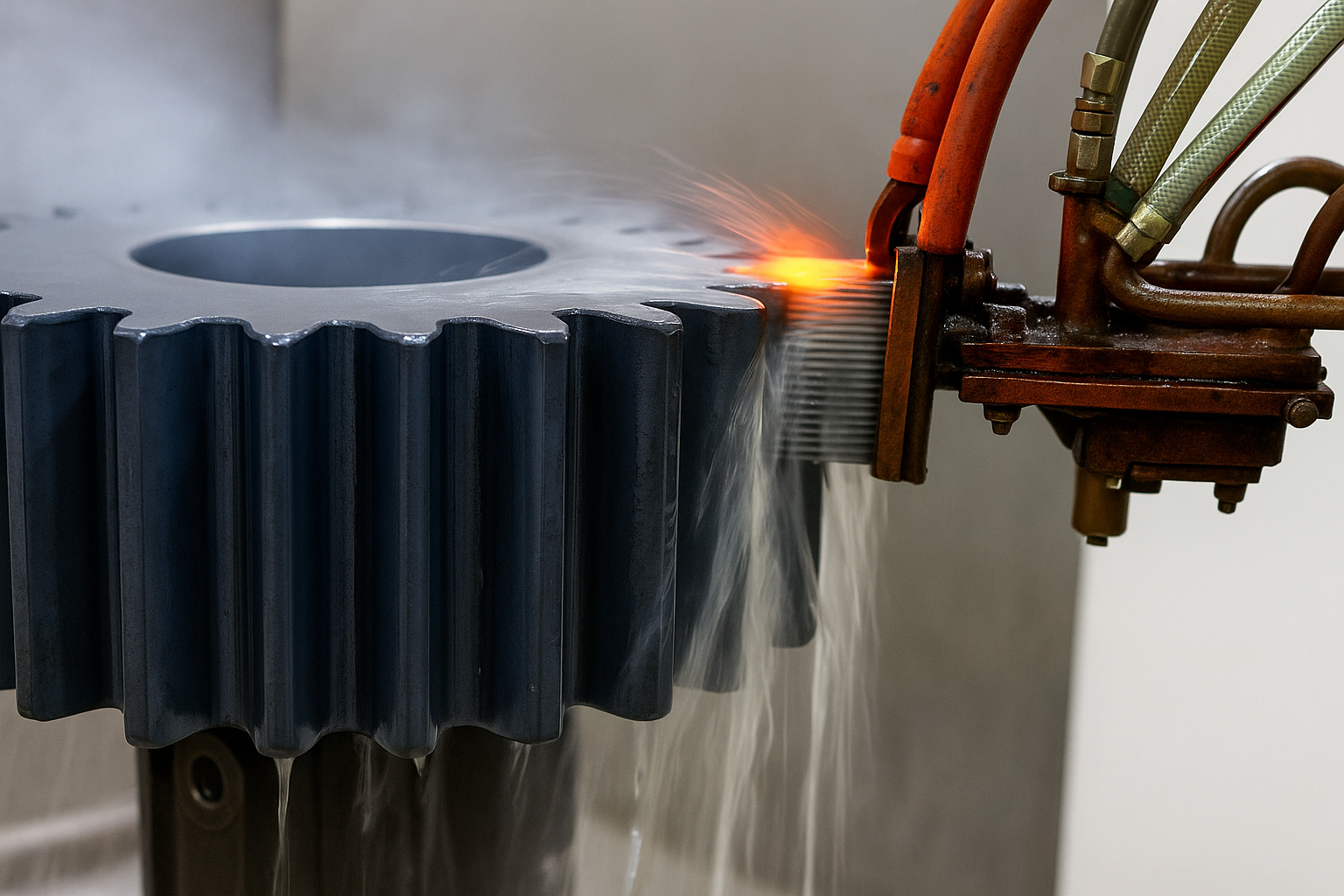

Heat Treatment

Hardness/strength to specification. Improved fatigue; dimensional stability.

Surface Preparation

Blast clean for coatings/fit. Improved adhesion; uniform look.

Why Choose AMSOL

Pressure-Ready Parts

Material breadth across stainless and nickel alloys. PFMEA/SPC discipline delivers repeatable sealing surfaces and durability in harsh media.

One-Roof Capability

Foundry, forging, machining, fabrication, and finishing run as one program—fewer vendors, faster launches, single accountability end-to-end.

Certified Quality

ISO 9001:2015 systems with CMM and spectro checks. Traceability and documentation withstand audits across upstream, midstream, and downstream programs.

CASE STUDY

AMSOL Manufacturing Ecosystem – Driving Industrial GrowthThrough Collaboration

Simplified Sourcing for Oil & Gas Assemblies

Relevant categories we supply—from prototypes to production—with documentation and traceability.

- Valve Bodies

- Flanges

- Pump Housings

- Manifolds

- Couplings

- Adapters

- Heat Sinks

- Enclosures

- Mounting Plates

- Pipe Fittings

- Sensor Housings

- Bushings