Amsol Capabilities

Sheet Metal, Built for Throughput

From DFM and nesting to laser, punch, bend, weld, and coat—we build precise sheet-metal parts and assemblies with repeatable quality, CMM checks, and line-ready packaging. One accountable partner from prototype brackets to serial enclosures with full traceability.

- ISO 9001:2015

- 40+ Years Expertise

- ASTM / DIN / EN / JIS

- 30+ Countries

One line for cut-to-coat flow

Integrated cutting, forming, welding, finishing, and dispatch under one roof.

- DFM reduces parts, welds, hardware, and total cost

- Smart nesting lowers scrap and stabilizes per-part pricing

- Tight bend control with calibrated tools and gauges

- Fixtures and jigs ensure weld repeatability across lots

- CMM and gauges verify critical interfaces and fit

- Batch coding, kitting, and on-time, damage-free deliveries

Production that scales cleanly

We lock processes, qualify assemblies, and maintain takt and cosmetics.

- Rapid samples validate flat patterns, bends, and clearances

- Process windows fixed for laser, punch, and forming

- Tool care prevents burrs, edge pull, and bend drift

- Cosmetic standards documented with panel masters

- Pack-out engineered for surface and corner protection

Amsol Sheet Metal Capabilities

From flat sheet to finished assembly

Lead Time

Quick prototypes; controlled ramps; predictable serial cadence

Tooling/fixturing

Hard stops, go/no-go gauges, and weld fixtures

Tolerances

Tight bends, true flats; CMM and gauge control evidence

Prototyping

Soft tools; T1/T2 loops; design trims closed fast

Quality

PPAP, FMEA, MSA; traceability and cosmetic AQL standards

Explore the processes, materials and finishes behind our sheet-metal parts.

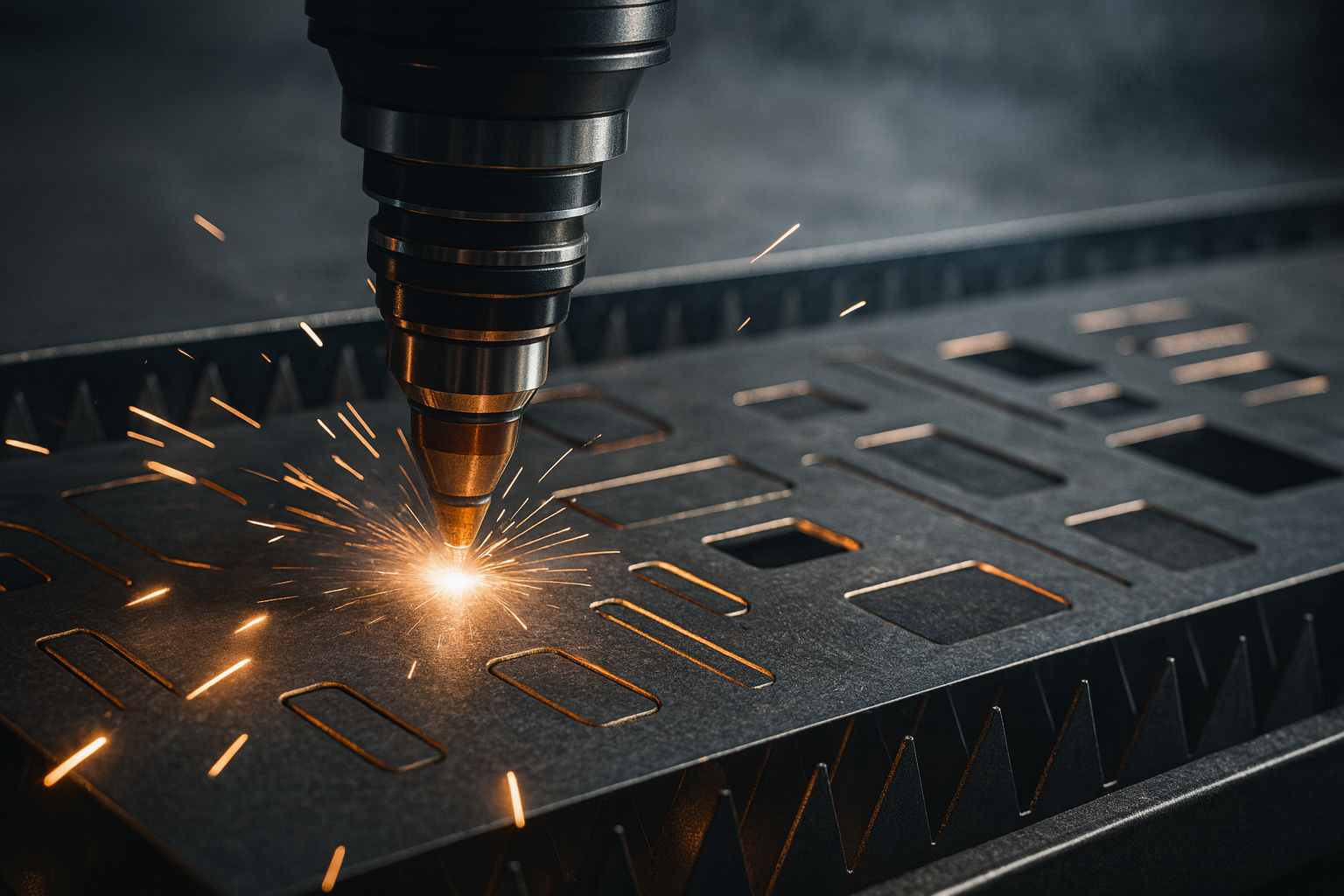

Laser Cutting

Clean edges, tight kerf control, smart nesting for material yield.

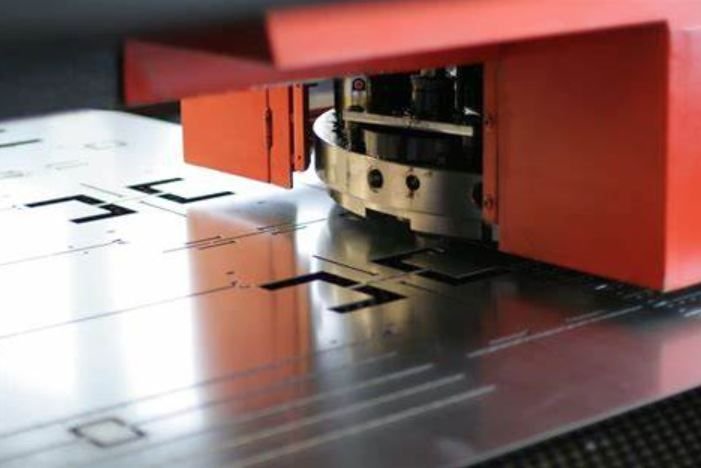

Turret Punching

High-speed holes, louvers, forms, efficient patterns with low burr.

Press Brake Bending

Calibrated angles and radii, consistent hems and flanges.

Welding & Assembly

MIG/TIG/spot weld accuracy, fixtures ensure dimensional stability.

Hardware Insertion

PEM, studs, standoffs installed, repeatable pull-out performance.

Stamping

Progressive or single-hit tools, volume efficiency with consistency.

Mild Steel (CR / HR)

Stainless Steel (304 / 316)

Aluminium (5052 / 6061)

Galvanized Steel (GI)

Electro-galvanized (EG)

Pre-painted Sheet (as sourced)

Powder Coating

CED (Cathodic Electrodeposition)

Zinc Plating (Clear/Yellow)

Anodizing (Aluminium)

Passivation (Stainless)

Brushing / Polishing

Grain / Bead Blasting

Laser Marking

Get the Brochure – Everything You Need in One Place.

Discover expert tips on design, materials, geometry, and tolerances—download the brochure now.